How Watches Work: What Is An Automatic Watch And What Different Types Of Winding Weights Are There?

Welcome back to another installment of How Watches Work. Today, we’ll be discussing automatic watches. We’ll take a look at not only what they are, but also how they came to be, how they work, and what different types there are. Whether you’re new to watches, a veteran collector, or simply a curious enthusiast, there will no doubt be something in this article that will help you better understand these miraculous ticking machines we love so much. So prepare yourselves, we’re about to jump in.

To get our first question out of the way, an automatic watch is a mechanical watch that winds itself through the user’s movement. Being a mechanical watch, an automatic watch does not use a battery. Instead, the mechanism inside, known as the movement, keeps time through an elaborate system of springs, gears, and levers. Whereas a traditional mechanical movement requires manual winding periodically, if worn regularly, a properly maintained automatic movement will conveniently keep time without any further user involvement.

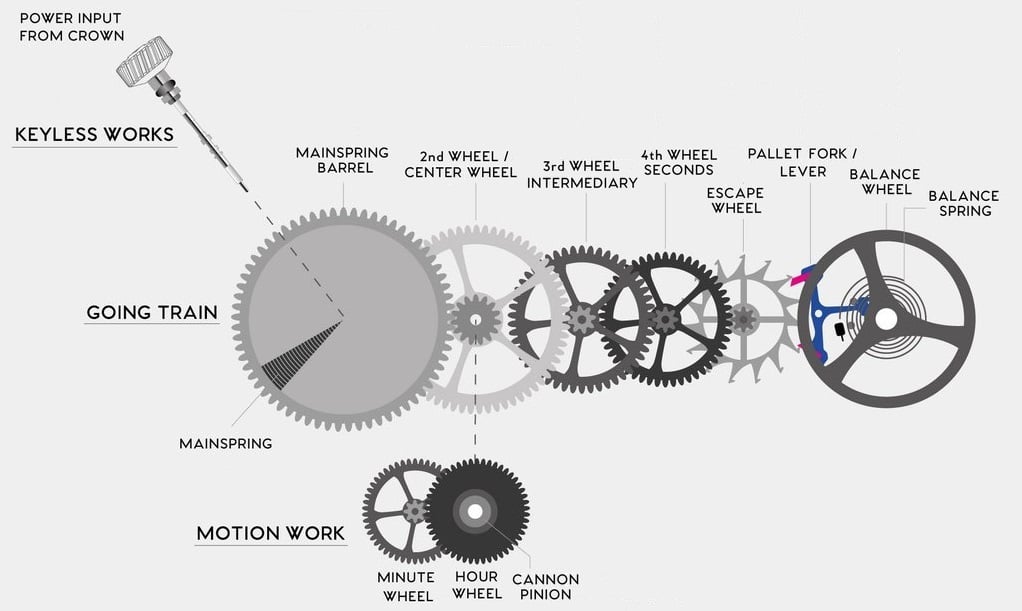

Understanding a basic mechanical movement

Before we dive further into automatic movements, let’s look at how basic mechanical movements work. This fundamental knowledge will give better context to everything we’ll discuss in the remainder of this article. The diagram below rearranges the basic movement components into a line. This will (hopefully) help you visualize my explanation clearly.

Tension in the mainspring powers the movement. The power is sent through gears known as the going train. The first wheel in this train is mounted upon the mainspring barrel. As the barrel rotates, it drives the 2nd/center wheel. This wheel rotates once per hour. The minute wheel, hour wheel, and cannon pinion on top of it drive the hour and minute hands in order to display the time. In traditional watches with an offset seconds sub-dial, power from the 2nd wheel travels through the 3rd wheel to the 4th wheel. This wheel rotates once per minute, and a small hand on its pivot displays the seconds.

Without anything to regulate the speed of these wheels, however, the mainspring would unwind almost instantly. Thankfully, the escape wheel and pallet fork (the “escapement”) serve as a brake, letting the energy escape incrementally. The escape wheel rotates as the pallet fork pushes it. This fork rocks back and forth thanks to a pin-shaped jewel (not visible here) on the underside of the balance wheel. This wheel uses the energy from the escapement to oscillate back and forth. The balance spring in the center expands and contracts to regulate the oscillations. This determines the frequency (beat rate) of the watch.

It all starts with external energy

Without a method of providing external power to the mainspring, however, none of this would be possible. In the example above, the user provides that power by simply turning the crown. This crown turns the stem, which turns a crown wheel. The crown wheel then turns the first wheel in the going train. As I mentioned above, this wheel is attached to the mainspring barrel, and it is called the ratchet wheel. It is responsible for delivering the external power to the mainspring. A click-mechanism prevents the ratchet wheel from turning backward, allowing the mainspring’s energy to release only through the going train. This is the basis for all manually wound mechanical watch movements.

The first automatic watches

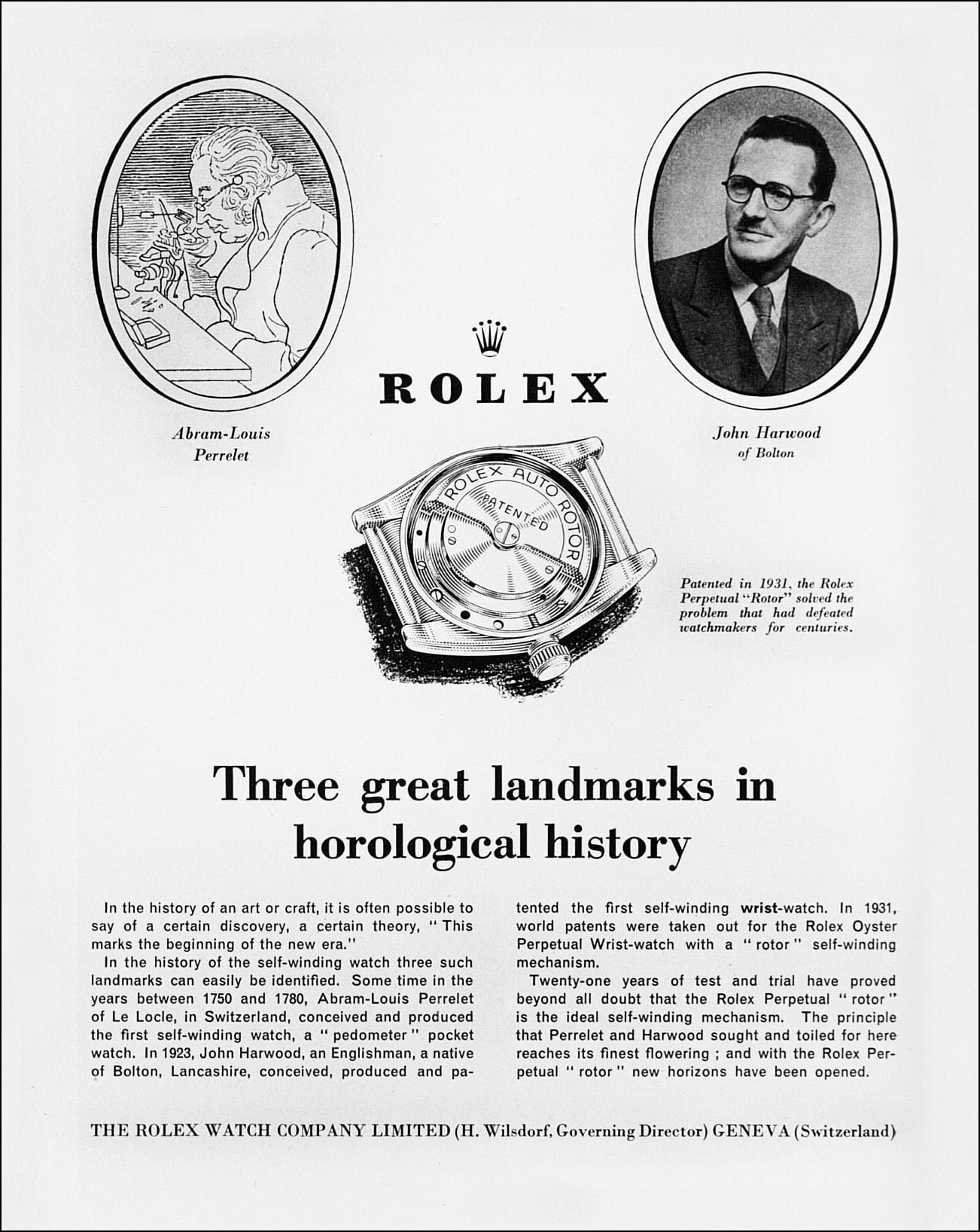

Nearly 250 years ago, however, watchmakers were already dreaming of ways to eliminate the need for manual winding. They sought to create an automatic pocket watch, which would harness the user’s natural motion to provide necessary external power to the mainspring. Though history from this time is murky, evidence suggests that in 1777, Abraham-Louis Perrelet was the first to create an automatic movement. His caliber featured a side weight that moved up and down in a 40-degree arc. Reportedly, by the user walking just 15 minutes, the resulting movement of this weight could wind the watch for a full eight days. Over the next 30 years, several other watchmakers would improve upon and manufacture this design, including Abraham-Louis Breguet.

One of five known examples of the earliest central-rotor watch movements, circa 1780. Image credit: watkinsr.id.au

Other 18th-century solutions

Though the side weight system was the most commonly used at the time, that didn’t stop other watchmakers from offering their own solutions. In 1778, Belgian clockmaker Hubert Sarton produced a movement with a centrally-mounted semicircular weight. The weight spun 360 degrees, both clockwise and counter-clockwise, and it wound the mainspring through a complex system of gears and chains. Out of all the automatic watches of this time period, Sarton’s rotor weight most closely resembles automatic rotors as we know them today. Only five known examples of these watches exist, however, as the design failed to catch on.

Before deciding to improve the side-weight mechanism, Breguet had successfully created an automatic movement using a “barrel remontoire” mechanism. Admittedly, exactly how this mechanism worked is beyond my level of understanding. At any rate, it proved both too complex and expensive to manufacture and sell, and Breguet abandoned the idea. In 1806, a single watch in which the entire movement acted as a winding weight was produced. One more solution, known as the center-weight, was also developed. In movements of this type, a centrally mounted weight swung in a 180-degree arc, stopping when it bumped against a supporting bridge. Although a few makers produced these, it is unclear who originally created the design.

A hard sell

Despite these various solutions, by 1810, automatic pocket watches had simply not caught on. With little incentive to keep innovating or producing them, manufacturers set the idea aside for over 100 years. It is important to note that Perrelet’s original side-weight design was indeed the most influential solution of the period. Many people today, however, wrongly assume that Perrelet invented the central rotor. Perhaps because the side-weight failed to survive till the modern era, the modern Perrelet company now chooses to use the rotor as a symbol of its own history. It is Hubert Sarton’s rotor design, however, that most closely resembles automatic movements as we know them today.

Oddly enough, though, Sarton’s central rotor design was actually not the first to make its way into wristwatches. It was, in fact, the center-weight “bumper” design that would spawn automatic watches in the modern era.

Harwood’s bumper automatics

During World War I, soldiers had found wristwatches quite useful, and after the war, wristwatches exploded in popularity. Of course, as they were subject to much more movement than their pocket-dwelling forebears, automatic winding finally seemed like a logical idea. In the early 1920s, British watchmaker and former soldier John Hardwood pioneered the first automatic wristwatch, receiving a patent for its design in 1924. Harwood’s watch used a hammer that rotated about 230 degrees to transfer kinetic power through the ratchet wheel to the mainspring. Inspired by the way a seesaw bounces off the ground, Harwood’s unidirectional winding weight bounced off of spring-loaded bumpers. Clockwise movement wound the watch, while counter-clockwise movement idled the winding mechanism. These had a power reserve of roughly 12 hours.

Interestingly, though, it was not solely the pursuit of automatic winding that originally inspired Harwood. Rather, it was the quest for a more robust case. Harwood had noticed that both the openings in watch cases and the action of daily winding through a crown allowed dust and moisture into the movements. This made them prone to damage, making regular servicing a necessity. To combat this, Harwood’s watches did away with the crown completely. Instead, the user needed only to set the hands by rotating the bezel. While the user could also wind the movement with the bezel, the bumping hammer eliminated the need to do so every day. With the help of A. Schild and Fortis, Harwood brought his watches to market in 1928. In three years, Harwood produced about 30,000 self-winding wristwatches, and they were a commercial success. Unfortunately, due to the Great Depression, the company folded in 1931.

The bumper lives on

The watch industry, however, realized the potential in Harwood’s design, and several brands produced bumper automatics of their own. Perhaps the most famous of these is Omega. From the late 1930s through the 1950s, the brand produced a variety of bumper calibers. They were hugely successful, remaining well-loved by vintage collectors to this day. Other notable brands that made bumper automatic watches include Mido, Tissot, Zenith, Vacheron Constantin, and Jaeger-LeCoultre.

The central rotor makes its return

Let’s take a step back to 1931. The same year that Harwood’s company closed, Rolex made a splash, debuting its patented Perpetual caliber 620. This was the first wristwatch movement with a centrally mounted rotor that spun 360 degrees. Though today we can credit Hubert Sarton as the original inventor of the central rotor in a pocket watch, at the time Rolex developed this caliber, no literature had yet been published on Sarton’s invention. Therefore, the brand likely developed the Perpetual independently. Though the rotor only wound the watch in one direction, its ability to freely spin 360 degrees led to more efficient winding than with a bumper. While Harwood’s bumpers, fully wound, had only had 12 hours of power reserve, the Rolex 620 was capable of over 30 hours.

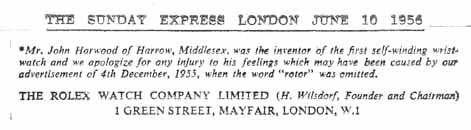

Rolex debuted the caliber in its waterproof Oyster line, which had already garnered significant critical acclaim since its release in 1926. The new combination of waterproofness and automatic winding helped further cement Rolex’s growing reputation as a leader in the field of functional tool watches. Perhaps this led the company to grow a bit too big for its britches, as it went on to falsely claim the title of “inventor” of the automatic wristwatch. John Harwood sued Rolex for this claim and won, causing the brand to issue a formal apology and include a photo of Harwood in its advertisements.

Modern rotor movements and how they work

The Rolex Perpetual caliber 620 was nevertheless the father of automatic rotor movements as we know them today. Although they are not the only automatic winding solution available in modern watches, central rotors are by far the most common. As mentioned previously, the Rolex Perpetual 620 featured unidirectional winding. Calibers with unidirectional winding still exist today, such as the Valjoux/ETA 7750. This trait gives the movement its signature “wobble.” In 1942, Felsa introduced the Bydinator caliber 410, the first rotor movement to feature bi-directional winding. Many popular movements today, such as the ETA 2824-2, also feature bi-directional winding. In 1948, Eterna introduced rotors with ball bearings. These provided greater support for the heft of automatic rotors, which had theretofore been supported by delicate jewel bearings. Ball-bearing rotors are the industry standard to this day.

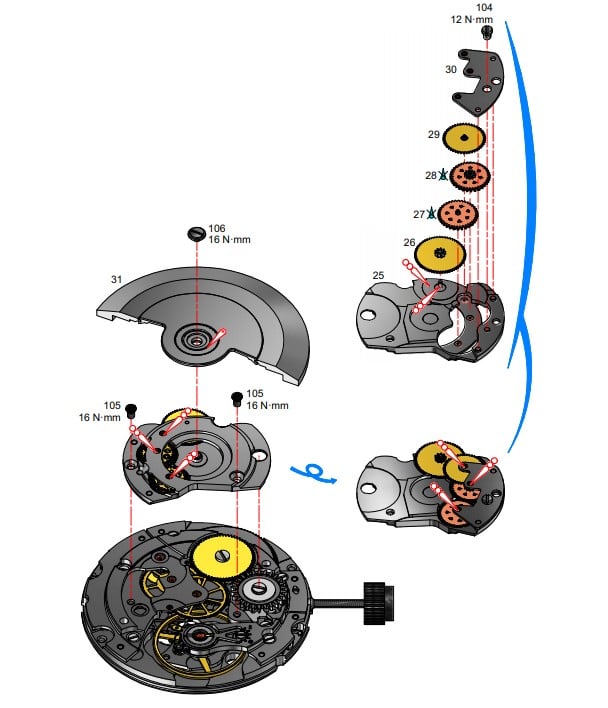

Using this diagram of the Sellita SW220-1, we can see how a standard bidirectional winding movement works. Minus the screws, the winding mechanism consists of parts 25-31. The rotor (31), attaches to the back of the framework (25). On this framework lies a series of four gear wheels. The reversing and auxiliary reversing wheels (27 and 28) allow bidirectional movement of the rotor to pass to the reduction wheel (29). The reduction wheel sends this energy to the driving wheel (26), which passes it to the ratchet wheel. As you hopefully remember, the ratchet wheel is mounted on top of the mainspring barrel. The ratchet wheel winds the mainspring and is the first wheel in the going train.

Alternative systems

Former IWC technical director Albert Pellaton developed the Pellaton winding system in the late 1940s, introducing it in the brand’s calibers 81 and 85 in 1950. Instead of directly geared wheels, the Pellaton system uses a cam and pawl system. The rotor sits on a pin connected to the jewel in the heart-shaped cam in this graphic. As the rotor turns, the cam rotates, engaging the circular ruby rollers on either side. The movement of these rollers engages the yellow pawl arms, which “climb” up the large, light blue automatic wheel. The automatic wheel then engages with the crown wheel (not present here) as on a standard manually wound movement. As mentioned earlier, the crown wheel turning winds the ratchet wheel on top of the mainspring barrel. This incredibly efficient system, seen here, makes use of every movement the rotor makes. IWC in-house calibers use Pellaton winding to this day.

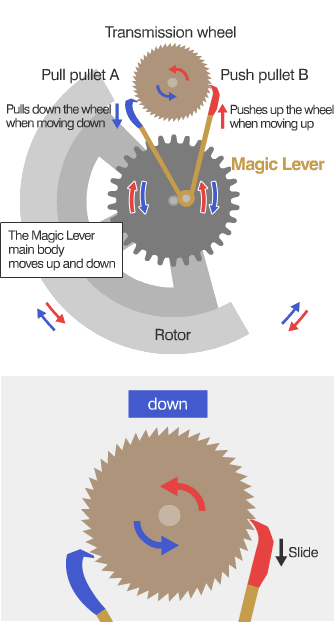

In the quest to simplify automatic winding even further, Seiko introduced the Magic Lever system in 1959. Like the Pellaton system, the Magic Lever is based on the movement of pawl arms. This system used just one wheel mounted underneath the rotor. On the bottom of this wheel was an off-center pin, which held the dual-armed Magic Lever. Because the pin was off-center, the base of the Magic Lever moved in a semicircle, pushing and pulling a transmission wheel. The transmission wheel directly delivered the power to the ratchet wheel (not pictured), which wound the mainspring. The majority of Seiko and Orient calibers today utilize this system, and it has proven to be one of the most efficient in the industry.

Regardless of their winding systems, all automatic movements today employ a disengaging mechanism that prevents the rotor from overwinding the mainspring.

Micro-rotors

By the mid-1950s, some manufacturers sought to reduce the thickness of their automatic calibers. One solution to this problem was the implementation of a micro-rotor. In 1954, Buren patented the first micro-rotor automatic movement, the caliber 1000. A year later, Universal Genève introduced its caliber 215. These movements featured tiny off-center rotors which laid flush with the bridges. To do this required rearrangement of the gear train with additional friction wheels and pinions to display the time. Additionally, micro-rotor calibers relocated the winding mechanism to the other side of the going train. The first micro-rotor calibers were, at 4.2mm thick, ironically not any thinner than concurrent central-rotor calibers.

In 1959, Piaget blew both Buren and Universal Genève out of the water with the introduction of its caliber 12P. The movement was only 2.3mm thick, making it the thinnest automatic movement in the world by a margin of nearly 0.2mm. Buren and Universal Genève continued to develop their micro-rotor calibers. By 1964, Buren had shaved its design down to just 2.85mm thick with its Intra-matic caliber 1321, and UG followed suit in 1966 with its 2.5mm-thick caliber 2-66. Hamilton watches of the period, such as the Thin-o-matic, made liberal use of the Buren calibers, leading Hamilton to purchase the brand in 1966. The Intra-matic caliber 1281 would serve as the base for the Chrono-matic (Caliber 11) automatic chronograph, one of the first three automatic chronographs ever and the first one with a micro-rotor.

Micro-rotor movements today

Today, while micro-rotor movements are rather rare in the realm of standard horology, they nevertheless maintain a home in the upper echelons of watchmaking. Patek Philippe, Piaget, Chopard, Bulgari, Czapek, and Vaucher all produce their own true micro-rotor movements, while A. Lange & Söhne utilizes a similar 3/4-size rotor. Micro-rotors these days are usually fashioned from gold or platinum. These heavier metals help the smaller rotor to rotate more and wind the movement more efficiently than older micro-rotors did. Bulgari is the current record holder for the thinnest micro-rotor movement with its caliber BLV138. Just 2.23mm thick, the BLV138 lives inside the Octo Finissimo, which has a total case thickness of just 5.15mm.

Peripheral rotors

Finally, we come to the last automatic winding weight on our list, the peripheral rotor. As far back as 1955, Swiss watchmaker Paul Gosteli filed a patent for a movement that featured a semi-circular weight that rotated around the movement cage itself. It is, however, unclear whether he actually produced any of these movements. In 1965, Patek Philippe patented its own version, and in 1969, the brand debuted its caliber 350.

The peripheral rotor caliber 350 was just 3.5mm thick, and it utilized an 18k gold half-ring rotor that spun around an outer track. As such, the winding gears were moved to the periphery. Due to this construction and the slimness of the movement, Patek could not use a traditional crown and stem. Thus, the brand positioned the crown on the backside of the watch through a hole in the case back. Unfortunately, however, caliber 350 was not perfect. The crown’s position often caused the movement to pick up moisture and dirt from the wearer’s wrist. Additionally, its particular bidirectional winding system was unreliable. In 1979, in response to the ultra-thin quartz watches taking over the industry, Patek launched the I-350. This improved version featured unidirectional winding. In the next six years, the brand produced about 10,000 of these, before throwing in the towel on peripheral winding altogether in 1986.

A forgotten ambition?

For the next 23 years, not a single brand successfully created a peripherally winding caliber. Although Citizen attempted something similar in its Super Jet line, the ring rotors on those movements were still mounted on top of the movement, only not centrally. It seemed that the industry’s aspirations for true peripheral winding had fallen by the wayside. That is, until 2009 when unlikely player Carl F. Bucherer surprised everyone with the release of the peripheral rotor caliber CFB A1000.

Carl F. Bucherer worked for three years to bring this thoroughly modern peripheral rotor caliber into existence. Having acquired movement designer Téchniques Horlogères Appliquées in 2007, the brand was able to realize its ambitions and create the first peripherally wound caliber in over two decades. While the movement was not the thinnest on the market at 4.3mm, this slightly thicker construction enabled the use of a standard crown and stem. The movement utilized a tungsten ring weight, which rotated on top of spring-loaded bars with ceramic ball-bearing roller pins. This helped the rotor resist shocks. A series of four wheels and two clutch wheels on the periphery of the movement near the mainspring barrel allowed for efficient bidirectional winding, in contrast to the Patek Philippe 350. Through a series of other innovations, the CFB A1000 also provided more efficient manual winding, better shock resistance, and a more durable balance assembly.

Peripheral rotors today

After Carl F. Bucherer revived the peripheral rotor, several other high horology brands followed suit. Today, Vacheron Constantin, Breguet, Piaget, Cartier, Bulgari, and Audemars Piguet, among others, all offer peripherally wound movements. In this day and age, peripheral rotors serve a dual purpose. They allow watches to remain slim, while also offering an unobstructed view of the meticulously crafted calibers which they are a part of. Though Piaget puts up a great fight in the realm of slim watches, holding the record for thinnest manually wound watch, Bulgari currently holds the record for the thinnest automatic watch in the world. The Octo Finissimo Automatic Tourbillon, thanks to its 1.95mm-thick caliber BVL 288, measures just 3.95 tall.

Did you get all that?

And with that, we come to the end of our discussion on automatic watches. As always, I hope you’ve found this in-depth look both entertaining and educational. I sure learned a lot in the research process! If you have any questions or comments, drop them down below. We love hearing what you have to say. Be sure to check back next week for the next installment of How Watches Work!